Famous Access Computer Flooring Factories – Wood core raised access floor (HDM) – kehua

Famous Access Computer Flooring Factories – Wood core raised access floor (HDM) – kehua Detail:

Product description

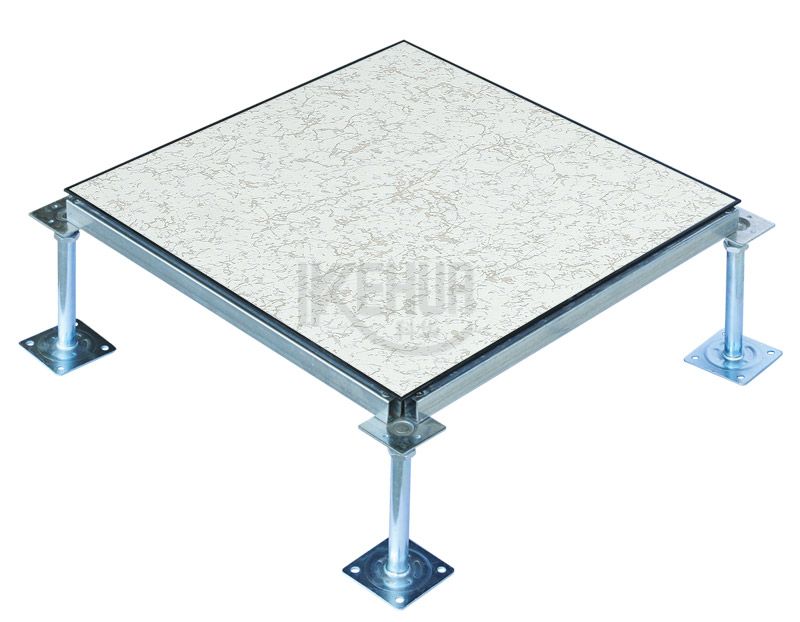

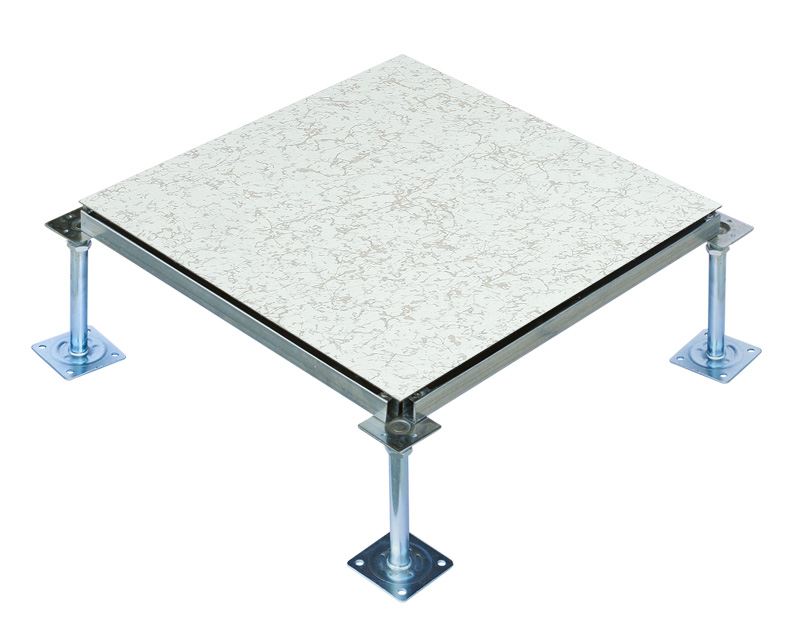

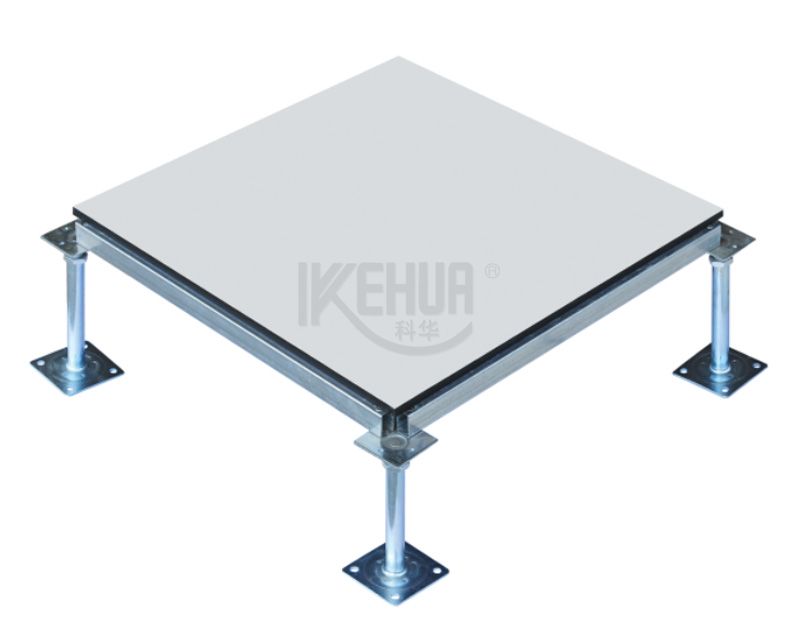

Green environment, high loading capacity and high wear resistance

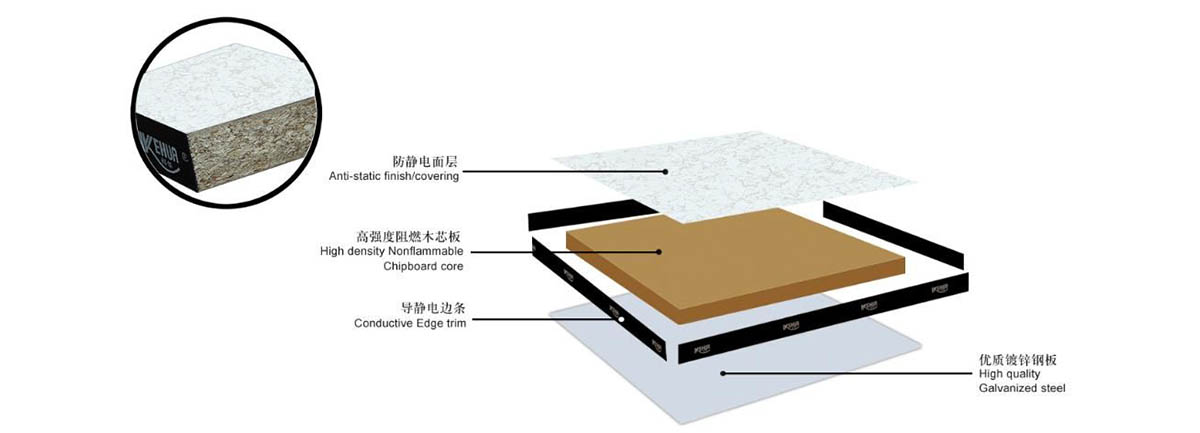

The panel is made of High-density particle board. Bottom is galvanized steel sheet / Aluminum sheet. Edge is 4 pcs black PVC trim along each side of the panel. Cover is HPL / PVC or others according to the customer’s requirement. This type flooring is as same as imported floor. This product technical performance is equivalent to the imported flooring products with a high loading capacity, high wear-resistant factor, light weight, low environmental pollution, foot feeling well, also have soundproofing, shockproof, fouling resistance, corrosion resistance, high wear resistance, effective pavement , long using life etc.

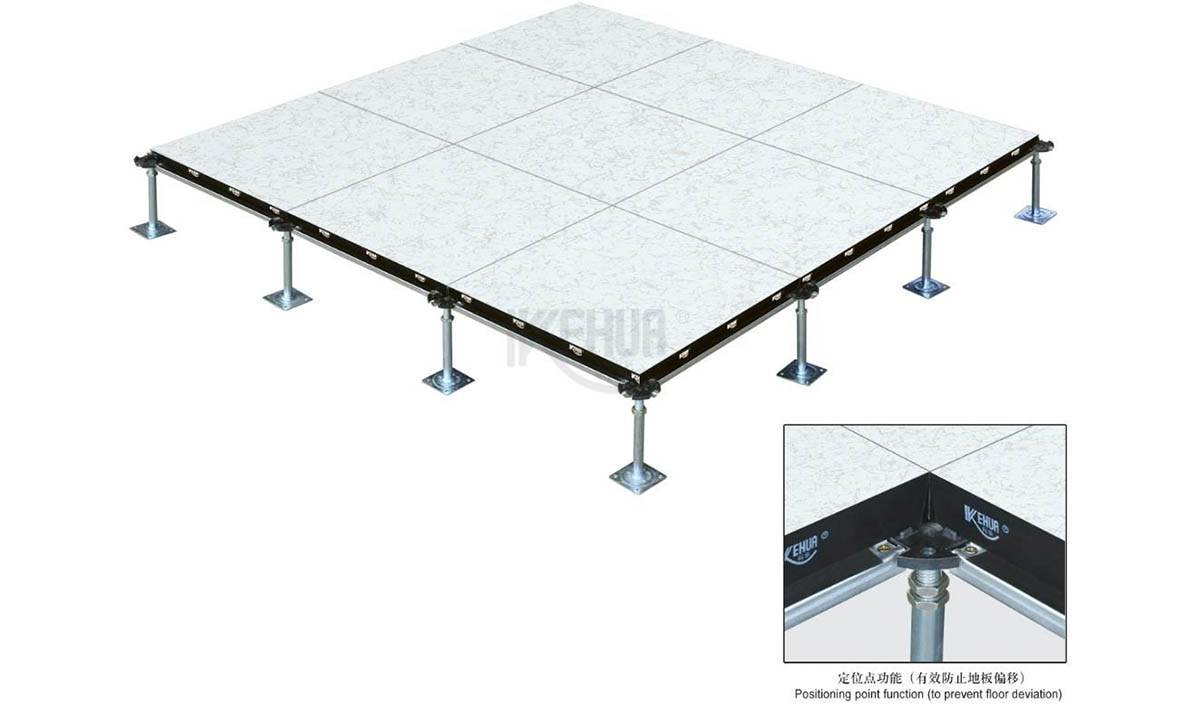

High density flame-retardant shaving core base material, high wear-resistant HPL veneer on the upper surface, four sides of guide electrostatic adhesive tape sealing, the bottom is embossed aluminum foil galvanized steel plate paste. The product is designed according to the highest fire protection requirements, and carries out strict performance and safety tests according to the national standards. The beam is made of square tube, the support is molded with steel, the height of the screw can be adjusted up and down, and the height of the finished surface can be selected according to the construction site.

HPL Panel is made by modern laminate technology, as a result of tropical layers on panel which make these panels advantageous.

Apart from the increase of the stability, it also has scratch and stain resistance properties that requires very low maintenance. HPL has an advantage of not requiring wax or any other maintenance that could produce static problems.

Due to this anti-static property, HPL panel complies with static electrical dissipation needs of computer rooms and clean room applications.

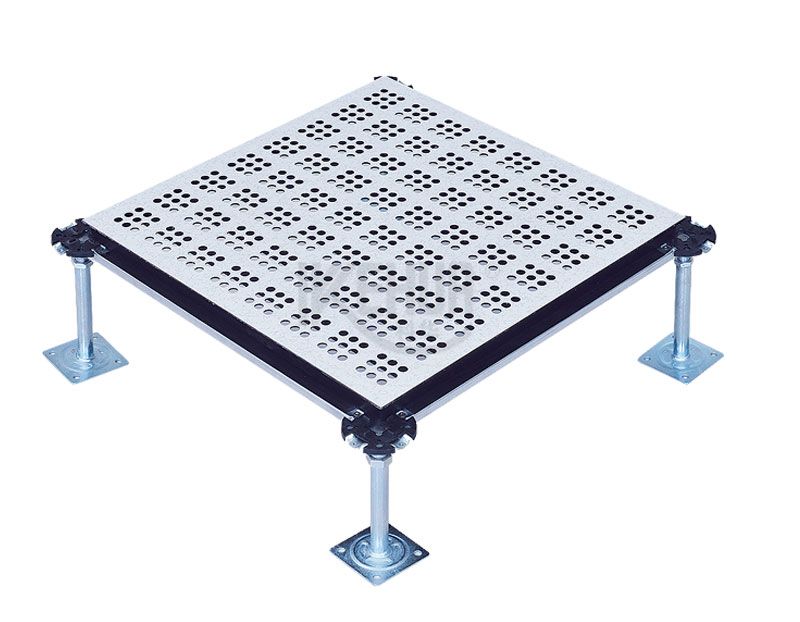

The center is made of high quality high density flame retardant thickened shaving pole core base material, the upper and lower parts are coated with high quality galvanized steel plate and extended to the sides around. Through the hook connection form, the closed ring is formed by stamping and riveting. Six sides are riveted with high quality galvanized sheet, four corners with or without corner keyhole, the surface can be laid with carpet, PVC or other materials; The bracket is molded with a plastic pad on the upper support, and the height of the finished surface is 70-150mm. The supporting structure around the beam or the supporting structure at the four corners can be used.

Features

1. Anti-static: composite anti-static floor with resistance stability, durable characteristics.

2. Pollution resistance: the use of raw material formula can reduce pore diameter, so that the stain will not go deep into the floor, to solve the problem of difficult cleaning floor.

3. No radiation: anti-static floor does not contain radioactive elements, safe, reliable, healthy, is a natural stone material.

4. Anti-aging: this floor quality is good, high hardness, up to 7 degrees Mohs, very long service life.

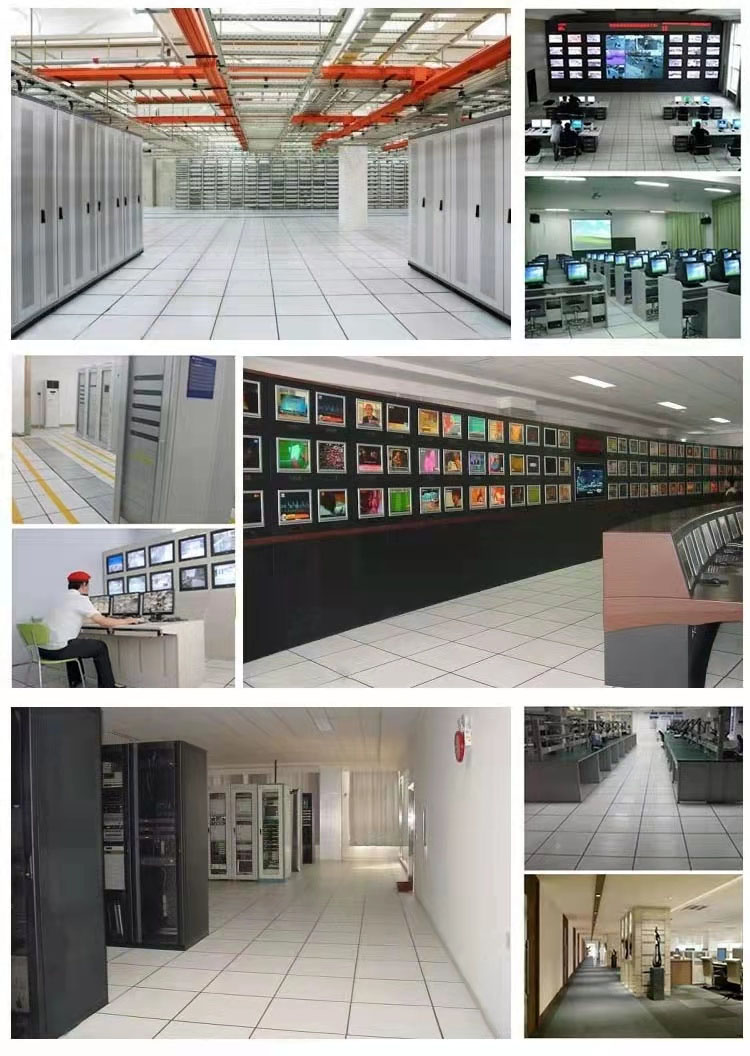

Application

The raised floor is mainly used in places where power is frequently used or where many cables are concentrated. The style of the raised floor is designed by special science, in the form of shelves, the surface of the floor is shaped above, the floor is supported by the support below, he is a piece by piece method. The most used are computer rooms, office buildings, intelligent office places, banks, data centers, hospitals, monitoring rooms, railways, subways, airport control rooms and so on.

Performance select chart

| Type | Specification | Concentrated Load(N) | Impact Load(N) | Ultimate Load(N) | Untimate Load(N/m2) | Dynamic Load(N) | Fire Protection | System resistance | ||||

| International | National | LB | N | KG | 10 | 10000 | ||||||

| FS1000 | HDM(B) | 600x600x40 | 1000 | 4450 | 453 | 670 | 13350 | 23000 | 4450 | 3560 | B1 | 1×106Ω~1×109Ω |

| FS1250 | HDM(Z) | 600x600x40 | 1250 | 5563 | 568 | 670 | 16680 | 33000 | 5560 | 4450 | B1 | |

| FS1500 | HDM(CZ) | 600x600x40 | 1500 | 6675 | 681 | 780 | 20025 | 43000 | 6675 | 5560 | B1 | |

FAQ

1. Can you provide samples?

We can provide free samples, but you need to pay for the freight in advance.

2. How to contact with you?

My whatsapp/wechat no is 008615532201529, hope we could communicate there.

3. When is the delivery time?

Normally need 15 days, but if for big quantity, will need more days.

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for Famous Access Computer Flooring Factories – Wood core raised access floor (HDM) – kehua , The product will supply to all over the world, such as: Peru, Lithuania, Wellington, We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!